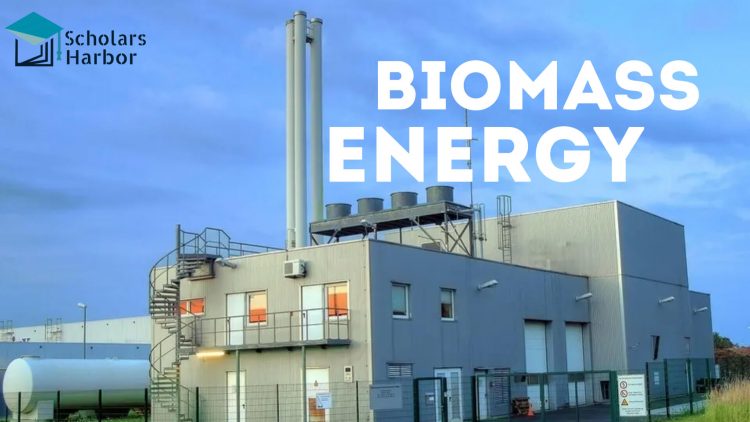

Biomass energy has the ability to contribute greatly to addressing the world’s energy demands while simultaneously being environmentally friendly and sustainable. Currently, it produces between 10 and 14% of the world’s energy, including 3% for transportation, but depending on the source, it might contribute up to 30-40% by 2050.

Multiple energy, environmental, and socioeconomic benefits of biomass energy are being provided in both traditional and modern applications, including transportation, heating, and electricity. In the past, humanity’s primary energy source has been biomass. There is a noticeable movement taking place right now from its traditional historical role to that of a temporary and increasingly modern source of energy.

Although there is a lot of controversy about its current and possible future contributions, it is an important part of future energy scenarios. The utilization of land, food security, biodiversity, the environment, climate change, a limited economy, sustainability, and other factors are all considered as being related to biomass energy.

Biomass energy conversion technologies

The potential of biomass in world energy makes it evident that there are a variety of feedstock’s available for use in both power-generating and biofuel conversion processes. There are numerous methods for converting biomass, and they vary based on variables such as the nature and quantity of biomass resources, economics, and the environment.

Two basic process approaches are employed to transform biomass into energy: thermochemical and biochemical. Mechanical extraction (with esterification), such as rapeseed methyl ester (RME) biodiesel, is the 3rd technique for producing renewable-energy from biomass. Combustion, liquefaction, biomass gasification, and pyrolysis comprise the thermal conversion processes.

01: Thermochemical conversion process

There are three fundamental thermochemical conversion techniques for biomass.

- Pyrolysis

- Gasification

- Combustion

1: Pyrolysis

Process of heating biomass in the absence of air is known as pyrolysis. During this process, the biomass is transformed into solid, liquid, and gaseous fractions. Using flash pyrolysis, which could convert the biomass into bio-crude with a maximum efficiency of 80%, Bio oil can be produced using pyrolysis. Bio-oil may be used in turbines and engines, as well as a feedstock for industries.

However, there are several issues that still need to be solved, such as corrosively and poor thermal stability. For some applications, it may be required to upgrade bio oils are produced by catalytic-cracking and hydrogenation, which lower the oxygen level and remove alkalis.

2: Gasification

Incomplete oxidation of biomass at extreme temps to create a variety of flammable gases is known as gasification. Low-calorie gas can be used as fuel for power plant. Syngas can also be composed of biomass. Combustion and gasification, operating together to produce a net efficiency of 40 to 50 percent ensures a high conversion rate.

Syngas made from biomass is used to create methanol and hydrogen, two fuels that can be utilized for transportation and other purposes. In order to make methanol, it is preferable to use either the indirect gasification of hydrogen or oxygen, both of which produce gases with greater calorific values.

3: Combustion

Burning biomass in an oxygen-rich atmosphere is known to as combustion., and it is used in a number of processes and equipment, including furnaces, burners, steam-turbines, & boilers, to convert chemical-energy that is stored in biomass into heat energy, mechanical energy, and electric power generation.

Despite any kind of biomass could be burned, it is only feasible to burn biomass when the humidity is under 50%. Biochemical conversion methodologies are more suited to high moisture content biomass.

02: Bio-chemical conversion

Three basic Bio-chemical conversion methods used for biomass are.

- Fermentation

- Anaerobic digestion

- Mechanical extraction

1: Fermentation

Sugar crops and starch crops are fermented commercially on a massive scale to make ethanol In a lot of places. The biomass is degraded, enzymes convert the starch to sugars, and sugars are converted into ethanol by yeast.

Distillation is an energy-intensive process used to purify ethanol; it can yield 450 liter of ethanol from one thousand kg of dry corn. This method’s solid waste product can be fed to pets, and sugar cane molasses can be used for later gasification.

2: Anaerobic digestion

Hydrocarbon is immediately converted to a biogas, during anaerobic digestion. It consists primarily of methane and CO2, with tiny quantities of other gases including H2S. Bacteria metabolize biomass in aerobic environment, forming a gas with energy equal to 20–40percent of the material’s lower heating value.

Anaerobic digestion is an extensively utilized, commercially tested technology that produces grid connected electricity with a least capacity of 1 MW. The merits of the recommendations for increased capacity, such as novel technological configurations, patterns of power consumption, economies of scale, etc., may be taken into consideration.

3: Mechanical extraction

Oil is created through the mechanical conversion process known as extraction from different biomass crops including cotton, ground nuts, and others. After the oil has been extracted, a cake-like material remains that can be utilized as cattle feed.

Cite this Article

| Author: | Scholars Harbor |

| Year: | 2022 |

| Title |

Biomass Energy and its Conversion Technologies – Explained |

| Publisher: | Scholars Harbor |

| URL: | https://scholarsharbor.com/biomass-energy-and-its-conversion-technologies-explained/ |

Discussion about this post